- Products

- New Products

- Featured Products

- Color and Print Themes

- Blood Pressure Measurement

- NIBP / Vital Sign Monitors

- Digital Aneroid Sphygmomanometers

- Palm Aneroid Sphygmomanometers

- Pocket Aneroid Sphygmomanometers

- Pro's Combo Sphygmomanometers

- Multicuff Sphygmomanometers

- Clock Aneroid Sphygmomanometers

- Mercury Sphygmomanometers

- Home Blood Pressure Measurement

- Adcuff +

- Gauges

- Bulb & Valves

- Disposable Cuffs

- Reusable Cuffs & Bladders

- Sphygmomanometer Accessories

- Sphygmomanometer Parts

- Caseware

- CPR / Airway

- EENT

- Instruments & Accessories

- Laryngoscopes

- Penlights

- Pulse Oximeters

- Stethoscopes

- Thermometry

- Vital Signs Monitors

- Solutions

- About ADC

- Learning Center

- Support

- Blog

- Contact

ADC Quality Control

Our vision for quality is a single sentence that becomes a powerful tool in the hands of our employees:

"ADC is dedicated to providing competitively priced products and services that consistently meet or exceed the requirements and expectations of our customers through the continuous improvement of our quality system."

Our quality control formula is at work in every step of the manufacturing process, including:

International Standards

ADC maintains a quality management system based on national and international standards and regulations. We employ superior in-house IQC based on ANSI/ASQC Z1.4 series standards.

Domestic assembly of a sphygmomanometer unit.

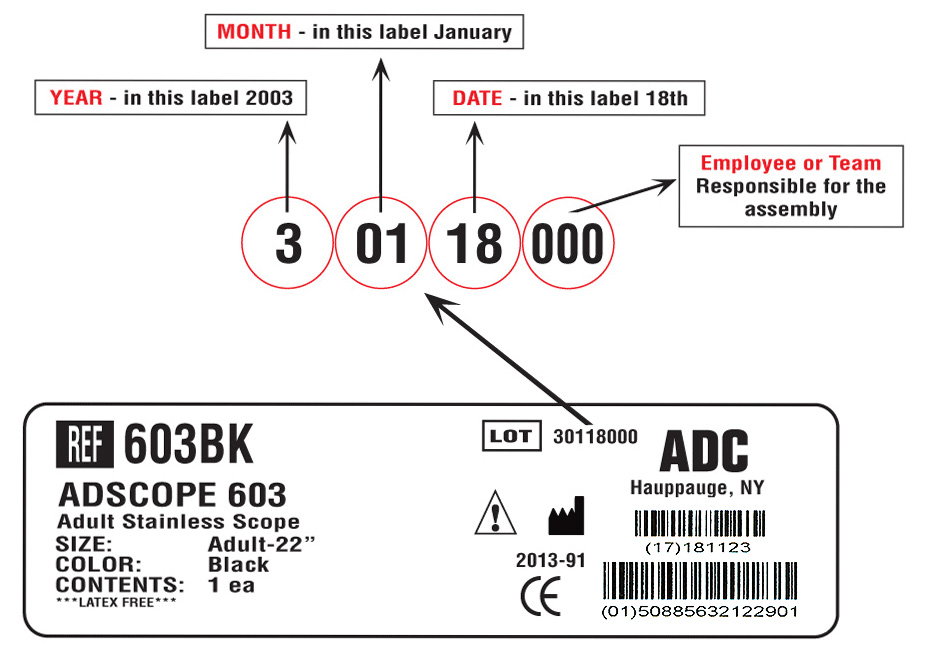

Domestic assembly of a sphygmomanometer unit. Explanation of our lot numbering system.

Explanation of our lot numbering system. Some of our proprietary testing equipment

Some of our proprietary testing equipmentInspections

While every component is inspected in our New York facility, critical components are subject to more rigorous incoming quality control (IQC) and testing. We empower all of our employees to reject non-conforming materials during the assembly and packaging processes, ensuring that our entire workforce is dedicated to producing the highest-quality devices. Our finished QC and bench-testing ensures conformance to design criteria and our own demanding standards of workmanship. We use our own proprietary QC equipment, all located in our New York facility, to test every shipment to our internal standards.

Traceability

Every product that undergoes some "value-added" work (e.g., inspection, assembly, packaging) receives a lot number that's incorporated into the item's end label. (And virtually every ADC product undergoes some "value-added" work.) The first five digits of the lot number indicate: year, month, and day of production. The final three digits represent the ID number of the employee responsible for assembly. Lot number tracking enables ADC to quickly isolate and correct any problems that may occur and provides you with the extra assurances you expect from your diagnostic product.

Domestic Content

We maintain both foreign and domestic quality control facilities – something few in the industry offer. Every critical inspection, assembly, and packaging function is performed in our New York facility to ensure complete control and unsurpassed performance. We hire locally, keeping jobs in the U.S. and promoting loyalty and teamwork amongst our staff. This helps ensure that we provide the best products and support services to our customers.

Proprietary Test Equipment

ADC utilizes a wide array of proprietary machines that test everything from gauge endurance and accuracy to stethoscope acoustics to cuff durability and bladder leakage. For example, our gauge and Adcuff™ endurance machines test these components to a destructive 30,000 cycles – three times the industry standard. We test our thermometers using NIST certified water baths and black body simulators at multiple temperatures in accordance with the ANSI standards. And our Clinical Dynamics AccuPulse™ NIBP Simulator tests the accuracy of our line of professional- and consumer-grade blood pressure monitors.

Product Warranties

We're committed to maintaining our quality standards even after purchase. ADC has some of the most comprehensive warranties in the industry. Several of our stethoscopes and manometers come with lifetime warranties. But coverage doesn’t expire with the warranty. Should your product ever need service, even out of warranty, it will be repaired for a nominal charge.