- Products

- New Products

- Featured Products

- Color and Print Themes

- Blood Pressure Measurement

- NIBP / Vital Sign Monitors

- Digital Aneroid Sphygmomanometers

- Palm Aneroid Sphygmomanometers

- Pocket Aneroid Sphygmomanometers

- Pro's Combo Sphygmomanometers

- Multicuff Sphygmomanometers

- Clock Aneroid Sphygmomanometers

- Mercury Sphygmomanometers

- Home Blood Pressure Measurement

- Adcuff +

- Gauges

- Bulb & Valves

- Disposable Cuffs

- Reusable Cuffs & Bladders

- Sphygmomanometer Accessories

- Sphygmomanometer Parts

- Caseware

- CPR / Airway

- EENT

- Instruments & Accessories

- Laryngoscopes

- Penlights

- Pulse Oximeters

- Stethoscopes

- Thermometry

- Vital Signs Monitors

- Solutions

- About ADC

- Learning Center

- Support

- Blog

- Contact

ADC Manufacturing

It Starts with a True Commitment to Quality

While many companies simply import pre-built medical products, we take a different approach. Our manufacturing process is designed from the ground up to focus on the quality of the components that we are using in our finished devices. Every component, large and small, must pass through our rigorous incoming quality (IQC) inspection process. Using statistically valid sampling plans and proprietary test equipment designed specifically for the medical devices we manufacture, we ensure that each and every component included in our finished products is of the highest quality.

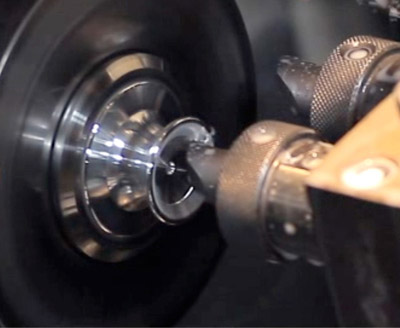

The Adflow™ manufacturing process: Our valves are precisely machined to ensure compliance with stringent leak test standards.

The Adflow™ manufacturing process: Our valves are precisely machined to ensure compliance with stringent leak test standards. Assembly of the Diagnostix™ gauge: Delicate movements are hand-assembled at the Nissei manufacturing facility in Shu Zhou, China. There are over 50 steps in the manufacture of our pocket aneroids, all made under exclusive contract by Nissei.

Assembly of the Diagnostix™ gauge: Delicate movements are hand-assembled at the Nissei manufacturing facility in Shu Zhou, China. There are over 50 steps in the manufacture of our pocket aneroids, all made under exclusive contract by Nissei. Creation of an Adscope™ chestpiece: Components are die cast and then precisely machined using CNC (computer numerical control) machines manufactured to exacting tolerances of 20 microns.

Creation of an Adscope™ chestpiece: Components are die cast and then precisely machined using CNC (computer numerical control) machines manufactured to exacting tolerances of 20 microns.Building Global Partnerships

We foster long-term contracts with some of the best ISO 9000 manufacturers around the world to ensure the best quality components. Most of our vendor partners are exclusive to us and have been for years, meaning our products are truly unique. We work closely with our vendor partners to guarantee that each and every component that comes to the U.S. for assembly meets the highest standards.

Assembled Here Using the Best Parts in the World

Any organization can import off-the-shelf products for sale in the U.S. At ADC, we reject the idea that such imports are good enough! Only by designing, inspecting assembling, and packaging in our New York facility can we ensure a core medical device will live up to the expectations of our customers. That’s why every single product that displays the ADC logo goes through, at the very least, extensive in-process quality inspections to ensure that they meet our demanding standards. Most of the core diagnostic products we offer are fully assembled in the U.S. from globally sourced components to guarantee that your experience with our products will be nothing short of excellent.

In addition, all of our component subcontractors are carefully selected and regularly audited to ensure they're consistently producing reliable, high-quality parts. ADC’s quality offices in Asia regularly perform on-site inspections to ensure that our supply chain contains only the best components for use in our finished devices.

Experience the Difference

Don’t just take our word for it, see for yourself how our manufacturing processes make every device we produce into a model of true craftsmanship. In the end, we're sure your experience will be nothing short of excellent.